This project was more of a proof of concept an anything. On paper a Inventables Carvey mill is capable of machining soft metals such aluminum and brass. I had never tried this though, but after finding out brass stock can be purchased off alli-express for rather cheap I decided to give it a go. (It is worth noting that the actual alloy makeup is likely not true brass and is probably cut with other cheap metals like lead. True brass would cost more but for the purpose of testing this works fine.)

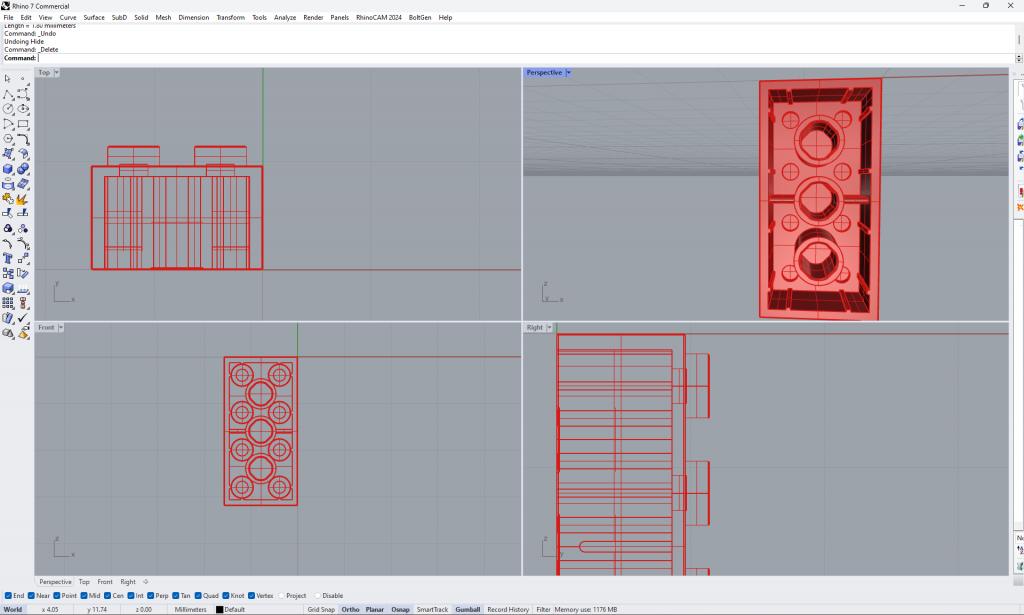

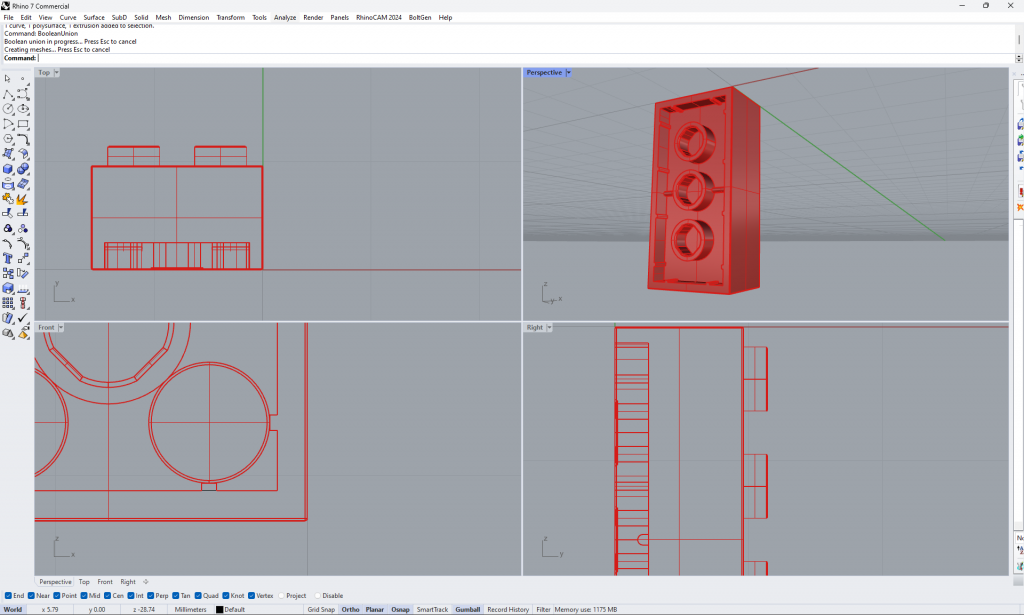

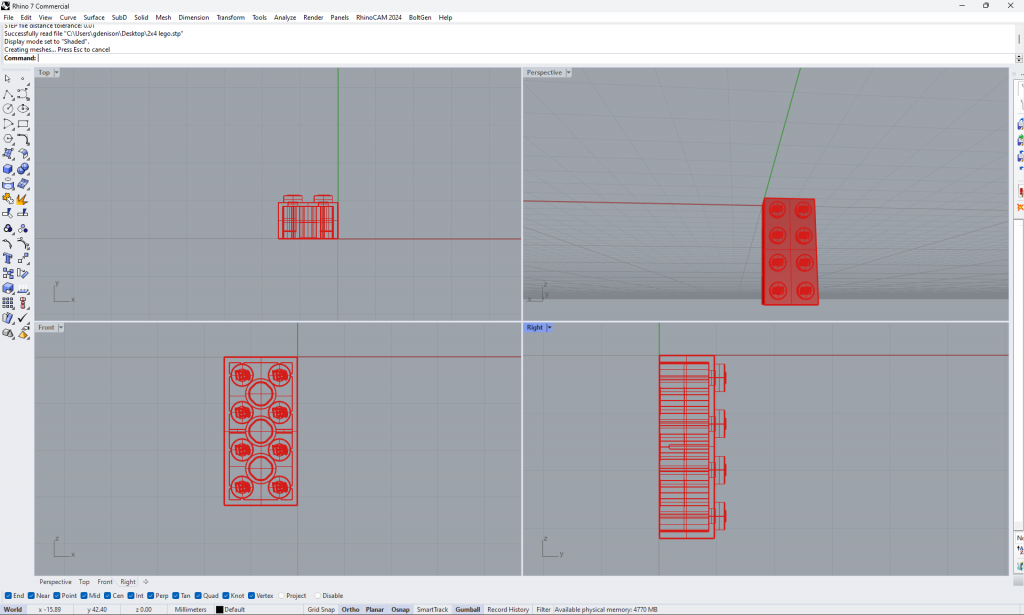

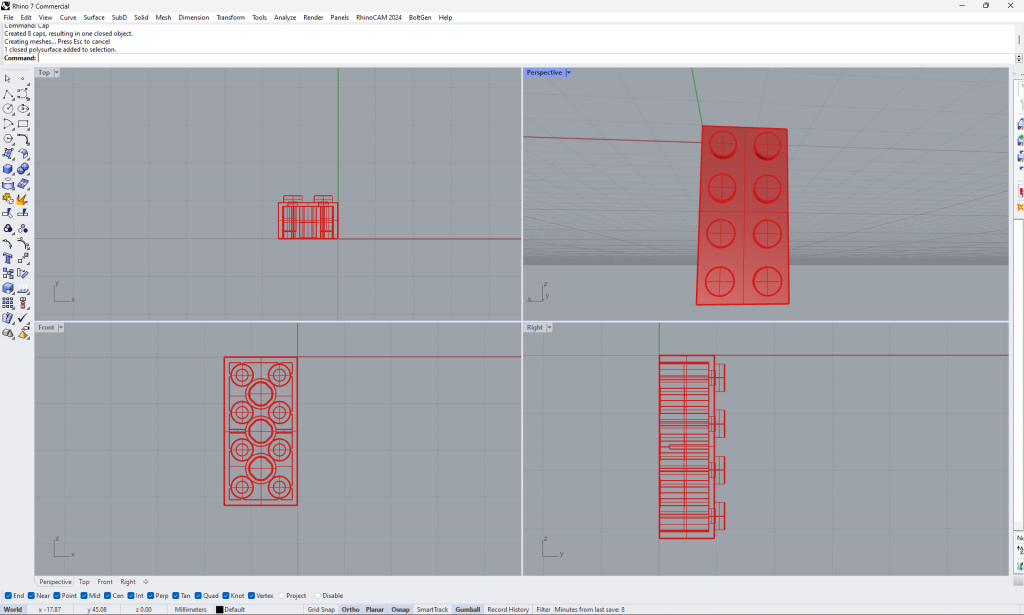

The first challenge is finding a model. I was able to find a Free Cad model of a 2×4 Lego brick. This model was a excellent start (Thanks Nick Turo-Shields). I did have to simplify it a little bit since my Carvey CNC was not capable of such small fillets and engravings. Using Rhino 7 I was able to remove the fillets and engravings.

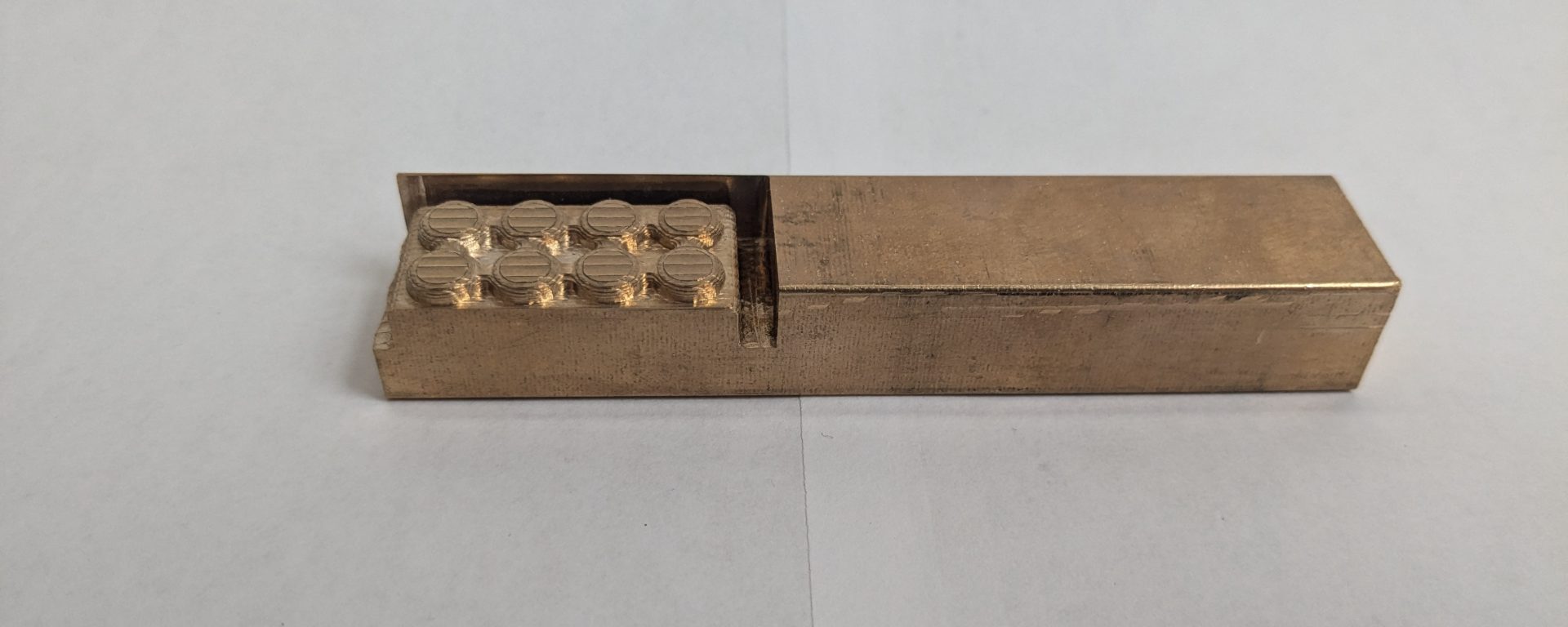

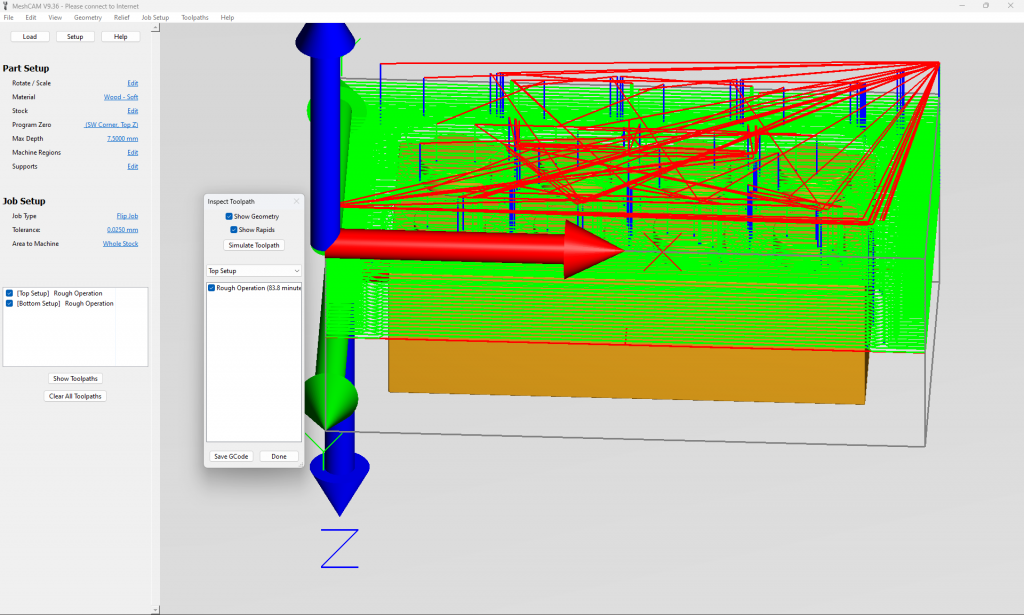

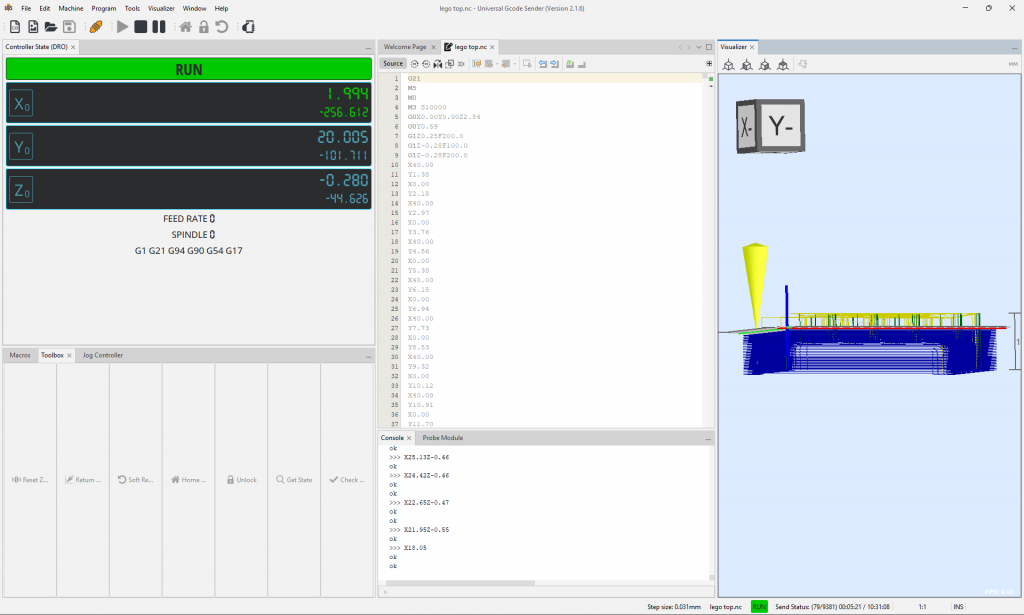

After this I exported it as a STEP file and imported into Mesh Cam and generated a G-Code file for the CNC. After fastening the stock to waste plate with VHB tape I zero all the axis and then let it run. It took all night to finish this cut, since I had to slow down the cutting speed to accommodate the harder material.

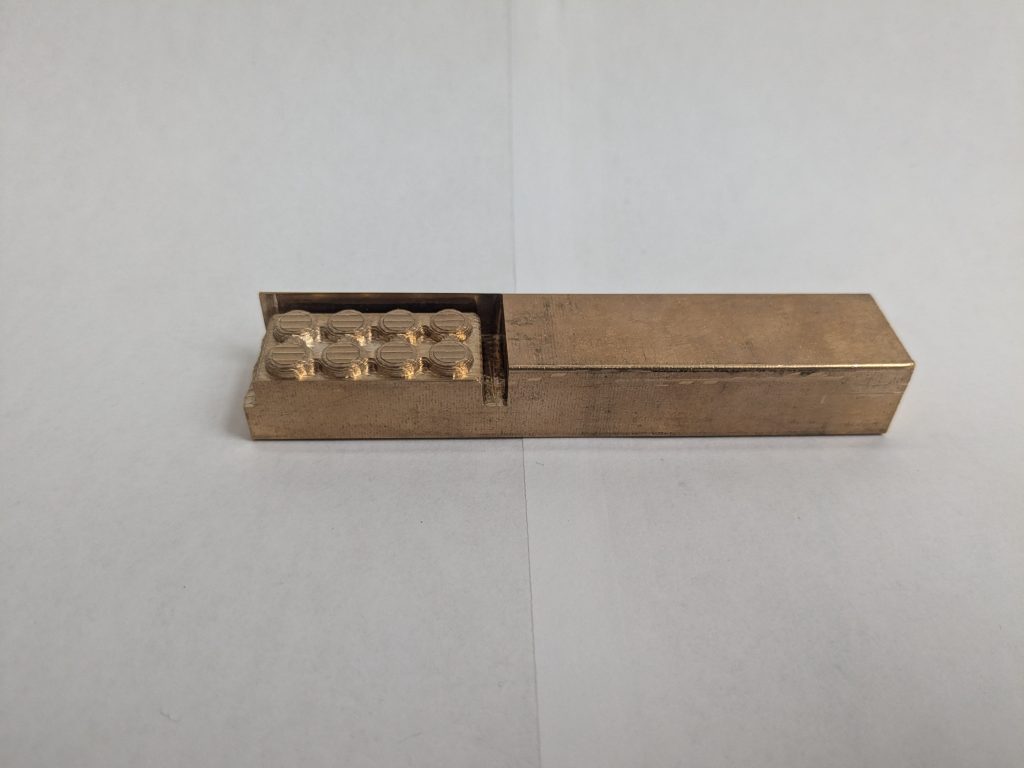

While it did cut the brass I was still struggling with getting the correct offsets. This is what is causing cuts to not be centered in the stock. The other problem is the fact that the fillets that I did leave on the model are still to much. You can see the artifacts that appear on the top of each stud.

After some close inspection of the g-code I believe that this may have been caused by setting Mesh Cam to make a roughing pass and accidentally disabling the finishing pass. With a little inspection the model though it is clear it can be further simplified. I am going to attempt to basically remake the model as simple as possible. Hopefully I this will help the artifacting and speed up the milling processes.